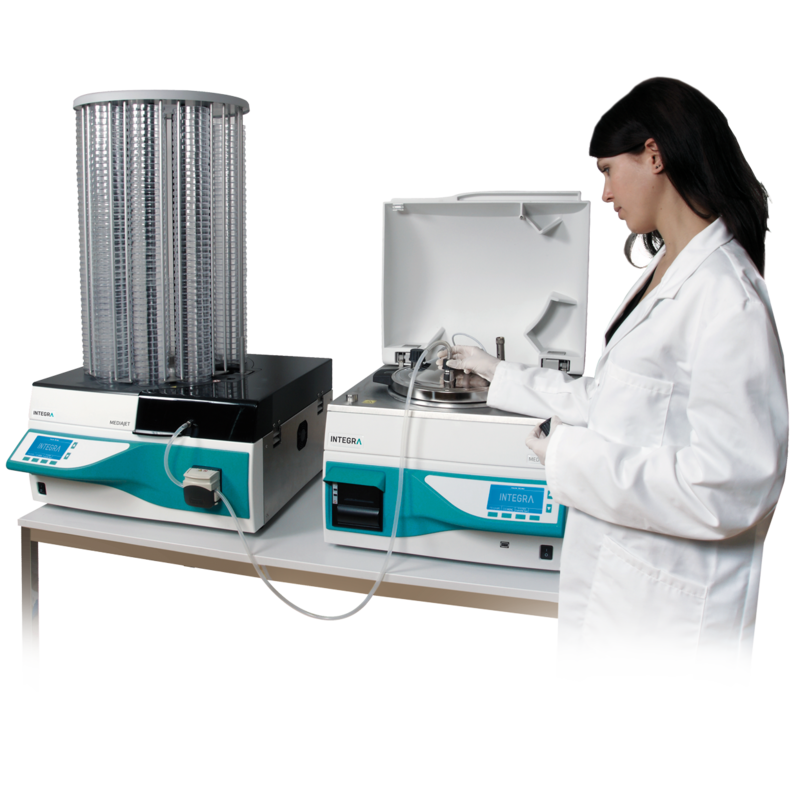

Media preparation

Description

Media preparation

MEDIACLAVE 10/30

Media Sterilizer

Media clave 30 liter

Fast, reproducible and safe media sterilization

The preparation of agar medium is a routine task in today’s laboratories. The typical workflow is to dissolve the components in a flask followed by sterilization in an autoclave. However, this procedure has several disadvantages.How it works

The MEDIACLAVE product range allows the rapid and gentle preparation of 1 – 30 L culture medium. Precise controlling and monitoring of temperature, time and pressure during the sterilization process guarantee constant high quality.

Safety

MEDIACLAVE is equipped with several independent monitoring systems for pressure and temperature, guaranteeing highest safety standards for the user and the working environment. The vessel lid is equipped with an autonomous overpressure safety valve and a burst disc in case all other electronic monitoring systems fail.

1) Adding Port

2) Overpressure Safety Valve

3) Dispensing Port

4) Temperature Probe Pt1000

Reliable Sterilization

The large and strong magnetic stirrer with adjustable speed and reversing rotation direction ensures homogenous media preparation over a wide viscosity range. A Pt-1000 temperature probe and microprocessor control of process parameters allow reproducible and complete sterilization of culture media.

Dispensing

MEDIACLAVE can be quickly and conveniently connected to the dispensing tubing of the automated Petri dish filler MEDIAJET. Alternatively, the peristaltic pump DOSE IT can be used to fill containers of more unusual volumes or shapes, e.g. quadrangular Petri dishes, bottles or flasks.

Large containers such as bottles can be filled by pressure dispensing.

Applications

MEDIACLAVE used for the preparation and sterilization of numerous types of culture media

Typical examples are:

- LB (Luria Bertani) Medium – primarily used for the cultivation of Escherichia coli

- Tryptic Soy Agar – general purpose medium used for culturing a wide array of microorganisms

- Blood Agar – for fastidious microorganisms

- Chocolate Agar – for fastidious respiratory bacteria such as Haemophilus influenzae

- MacConkey Agar – for Gram-negative bacteria

- Sabouraud Agar – for fungi

- Peptone solutions – for sample preparation

MEDIAJETPetri Dish Filler

Petri Dish Filler

Applications

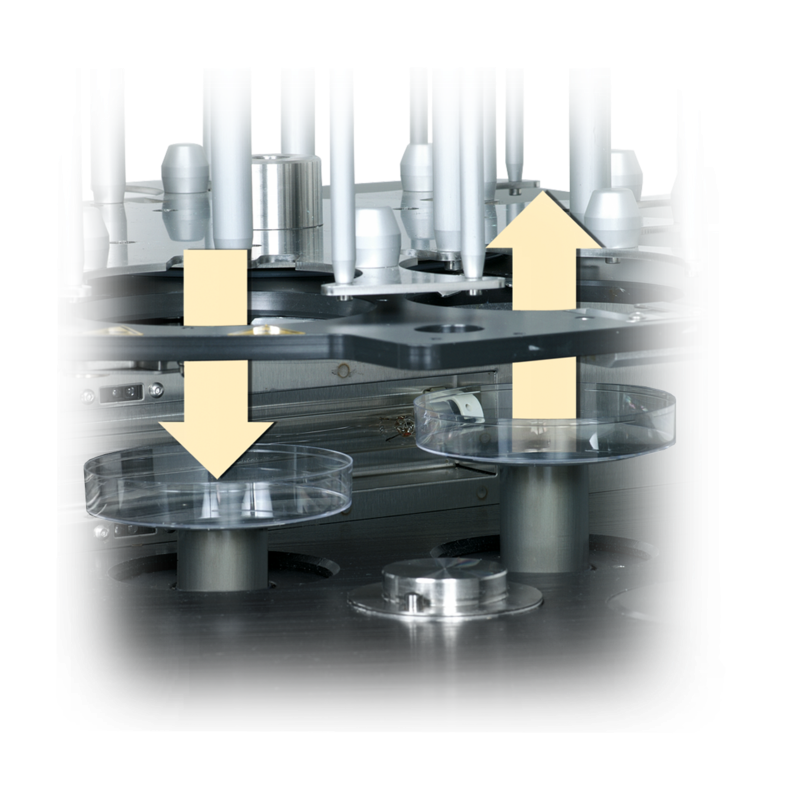

How it works

MEDIAJET offers the unique flexibility to fill Petri dishes of various sizes, Petri dishes with two compartments or test tubes of various diameters and length. At the same time, MEDIAJET requires only minimal bench space in the laboratory.

With the novel Feed-In/Stack-Out technology, MEDIAJET guarantees a reliable operation. Typical production variations in the diameter or shape of the Petri dishes are easily handled by the unit, as they are actively guided throughout the entire filling process. The optical dish sensors of MEDIAJET can be easily adjusted to virtually every Petri dish brand at the user interface level.

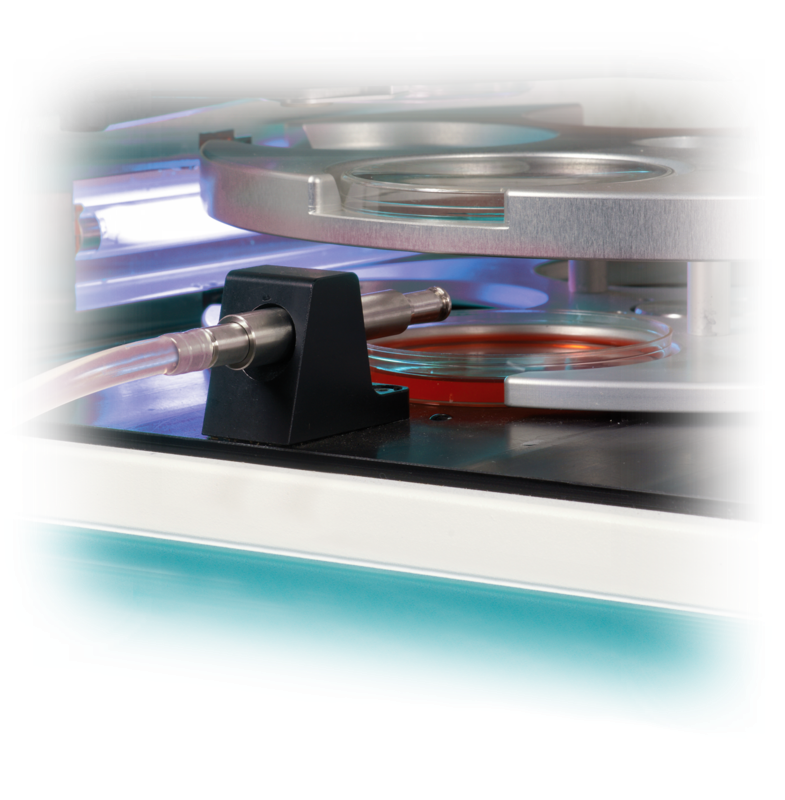

Eliminating sources of contamination

For consistent Agar plate quality, a clean environment is essential. The surface of the filling chamber is manufactured of a single piece of resistant PE, which allows efficient cleaning. In addition, MEDIAJET is equipped with a UV lamp extending over the full length of the rotor where the dishes are opened during the filling process. The lamp emits powerful 2.1 W UV-C radiation for optimal bactericidal activity in the area most vulnerable to contamination.

Different optionally available inkjet printer connection kits allow the connection of three different brands of inkjet printers (MARKEM-IMAJE, LINX, Domino – ). All inkjet printer systems permit to apply a wide variety of information onto the Petri dishes like alphanumeric text, expiry/production date or barcodes.

All supported inkjet printers allow side wall imprinting. Alternatively, dishes can be imprinted on the bottom using the LINX inkjet printer.

Reviews

There are no reviews yet.